Closing 25 Together

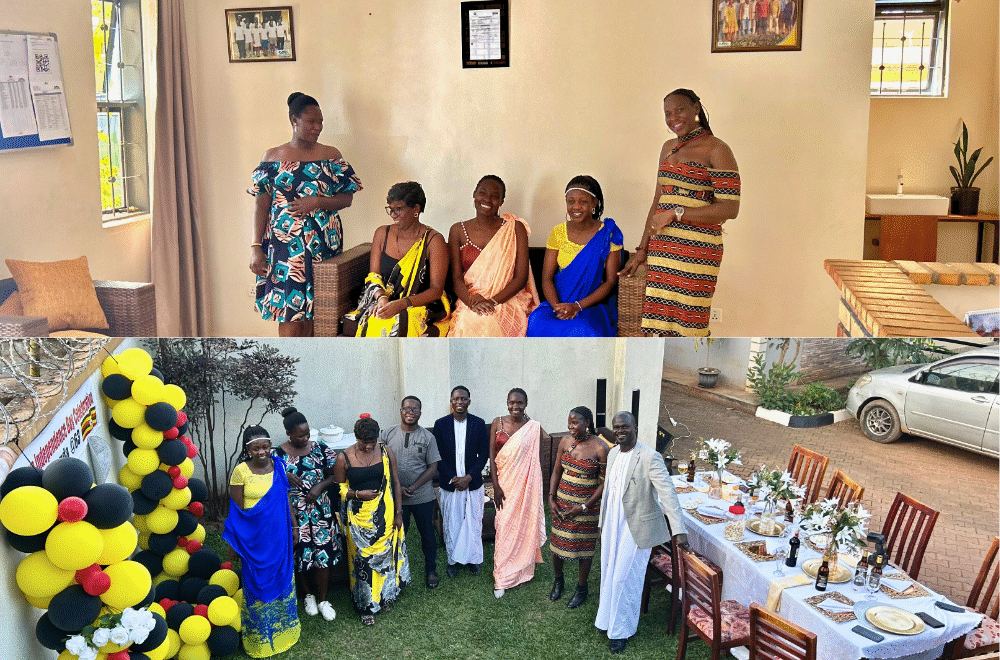

Rostwa held her end-of-year dinner at Mist Hotel, Entebbe, bringing together staff to reflect on the year and prepare for the one ahead.

During the event, the Managing Director, Eng. Emmanel Obwor delivered an end-of-year message, thanking the team for their commitment, hard work, and teamwork throughout the year. The address also focused on the year ahead, setting the tone for the next phase and encouraging everyone to remain aligned with the company’s direction.

Departments took Part in also took part in the program by highlighting their 2025 goals and reflecting on key milestones achieved collectively. This provided a clear view of where the company is headed and reinforced shared responsibility across teams.

The evening concluded with a dinner and a light social session, allowing staff to relax, connect, and celebrate the year’s progress in a warm and enjoyable setting.

As Rostwa Engineers closes the year, the company remains focused on strengthening its foundations, delivering meaningful impact, and working together toward the future guided by a continued commitment to Excellence and Value